- Home

- Products

- Hot

- About Us

- Services

- Industry

- Contact

Selecting the right vacuum pump size is crucial for ensuring efficient operation across various industrial applications. An appropriately sized pump helps maintain optimal performance, reduces energy consumption, and prevents unnecessary wear and tear.

Vacuum pumps are essential devices that remove gas molecules from a sealed space to create a vacuum, helping maintain controlled environments across a wide range of industries. These pumps are critical in sectors such as pharmaceuticals, electronics, and food production, where contamination-free environments are paramount to ensure product quality, safety, and reliability.

Vacuum pumps play a critical role in a variety of industrial applications, such as in pharmaceuticals, semiconductor manufacturing, and food processing, where they help create controlled environments by removing air and contaminants. As industries increasingly focus on reducing operational costs and improving efficiency, energy efficiency has become a key consideration.

Vacuum pumps are essential components in a wide range of industries, including pharmaceuticals, manufacturing, electronics, and food processing. They are critical for creating controlled environments by removing air and contaminants, ensuring the safety, quality, and efficiency of operations.

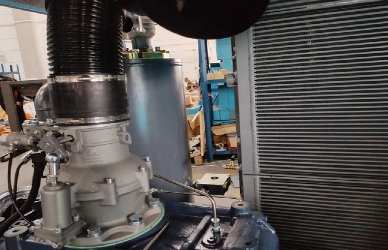

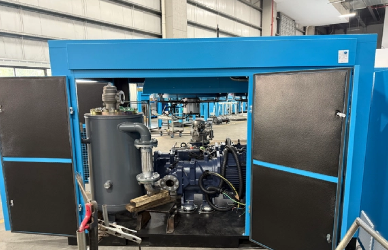

IntroductionAre you struggling to choose the right air compressor for your business? With so many options, selecting the ideal model can feel overwhelming. Understanding the differences between compressor types, especially the two-stage screw air compressor, is key to making the right decision.

IntroductionChoosing the right air compressor is vital for your operations. But should you go for a two stage screw air compressor or a simpler model?Air compressors are essential in industrial applications.