Powerful, Efficient and Performance

Air Compressors!

Air compressors serve as fundamental industrial equipment that efficiently transforms electrical power into potential energy stored as pressurized air. Our premium range of high-performance air compressors delivers consistent, reliable compressed air solutions for diverse applications across industrial, commercial, and DIY sectors.

Fleet of Luoyou Screw Air Compressors

Screw air compressors are the backbone of modern industry, valued for their reliability, efficiency, and versatility. By highlighting Luoyou’s technical innovations, customization capabilities, and commitment to sustainability, our screw compressors can be positioned as the go - to choice for businesses worldwide.

High Efficiency Air Compressor

High Efficiency – Modern air compressors are designed for optimal energy use, reducing operational costs while maintaining high output.

Versatility – Suitable for various industries, including manufacturing, construction, automotive, and pharmaceuticals.

Durability – Built with robust materials to withstand demanding work environments and extended use.

Low Maintenance – Engineered for minimal wear and tear, requiring less frequent servicing compared to other power sources.

Clean & Safe Operation – Unlike fuel-based alternatives, air compressors produce no harmful emissions, ensuring a safer workplace.

Cost-Effective – Lower long-term expenses due to energy savings and reduced maintenance needs.

Precision & Control – Adjustable pressure settings allow for precise application in pneumatic tools and automated systems.

Noise Reduction – Advanced models feature quiet operation, making them ideal for indoor and sensitive environments.

Compact & Portable – Available in various sizes, including lightweight models for easy transport.

Reliable Power Source – Provides consistent performance even in fluctuating conditions.

Technical Specifications

PM VSD Screw Air Compressor

Screw compressors are rotary positive - displacement machines that use two intermeshing helical rotors (a male rotor with convex threads and a female rotor with concave threads) to compress air. As the rotors turn, air is drawn into the inlet, trapped between the rotors and the housing, and gradually pushed toward the discharge end. The reducing volume between the rotors increases air pressure, delivering a continuous, pulsation - free flow of compressed air.

Oil-free Air Compressor

The compression chamber is completely free of oil, ensuring the discharged air contains no oil vapor, mist, or particulate contamination. This is critical for industries like:

Food & Beverage: Packaging, processing, and bottling (compliance with ISO standards).

Pharmaceuticals: Manufacturing of drugs, medical devices, and sterile environments.

Electronics: Semiconductor production, where oil particles could damage sensitive components.

Laboratory & Medical: Dental clinics, hospitals, and analytical instruments requiring clean air.

Vacuum Pump

Vacuum pumps are indispensable for any process requiring low-pressure environments, from industrial manufacturing to cutting-edge research. As a Shanghai-based air compressor manufacturer, expanding into vacuum pump solutions could diversify your product line, catering to industries like semiconductors, medical devices, and food packaging—all of which demand reliable, efficient, and contamination-free vacuum technologies. By aligning with trends like oil-free designs and smart controls, ensure to meet evolving market needs while maintaining a competitive edge.

Application

PM VSD Screw Air Compressor

- Manufacturing Powering pneumatic tools (drills, grinders), conveyor systems, automated machinery, and robotic arms.

- Food & Beverage Packaging (air - driven fillers, sealers), blow molding for bottles, and clean air for processing lines (oil - free models).

- Pharmaceuticals Air for tablet pressing, sterilization systems, and pharmaceutical packaging (requires oil - free compliance).

- Construction Powering jackhammers, spray guns, and concrete vibrators; used in portable compressor units for site work.

- Oil & Gas On - site compressed air for drilling, pipeline cleaning, and instrument air in refineries (explosion - proof models may be required).

- Mining Ventilation systems, rock drilling, and pneumatic conveying of minerals.

- Water Treatment Aeration in wastewater plants, air - driven pumps, and filter backwashing.

Oil-free Air Compressor

- Food & Beverage Packaging, brewing, bakery equipment.

- Pharmaceuticals Tablet pressing, sterile air for cleanrooms.

- Electronics Semiconductor manufacturing, PCB assembly.

- Medical & Dental Hospital air systems, dental chairs.

- Aerospace & Aviation Pneumatic control systems, component testing.

- Chemical & Laboratory Analytical instruments, gas supply systems.

Vacuum Pump

- Manufacturing Vacuum forming (plastics), metal degassing, leak testing, and packaging.

- Semiconductor Deposition/etching in chip fabrication, thin-film coating.

- Medical & Pharma Sterilization, vacuum drying of pharmaceuticals, and lab centrifuges.

- Food & Beverage Vacuum packaging (延长 shelf life), bottling, and dairy processing.

- Aerospace Testing aircraft components, satellite deployment, and space simulation.

- Research & Labs Mass spectrometry, vacuum furnaces, and cryogenics.

- Environmental Waste management (gas extraction from landfills), water treatment.

FAQs

Why Luoyou Compressor?

Luoyou Compressor is a renowned air - compressor manufacturer in Shanghai, and there are several reasons for its popularity and competitiveness, as follows:

Long - standing Experience and Scale: Established in 1998, Luoyou Compressor has accumulated rich experience in the compressor manufacturing industry for many years. With 101 - 500 employees and an annual revenue of USD10,000,000 it has a certain scale, which can ensure stable production and service capabilities.

Diverse and High - quality Products: It mainly produces air compressors, screw compressors, blowers, and other products, covering a variety of types, including fixed - speed air compressors, permanent magnet variable - frequency drive screw air compressors (oil - lubricated, oil - free, low - pressure, and medium - pressure models), as well as refrigerated dryers. Its products are widely used in machinery, food, medical, electronics, textiles, automotive, minerals, building materials, and other industries, meeting the needs of different industries.

Excellent Product Performance: The Company's Air Ends adopts the premium Hanbell body, which has been verified in the market over the decades since its launch. It has advanced technical quality in terms of air quality, energy conservation, and high reliability. It realizes balanced compression, with smaller vibration and lower noise. Moreover, it uses water instead of oil for lubrication, cooling, sealing, and noise reduction, providing 100% oil - free air, which is environmentally friendly.

Strict Quality Control: Luoyou Compressor adheres to technological development and continuous innovation, strictly follows the production management under the CE and ISO9001 international quality systems, and has passed the Class 0 certification, ensuring that each product meets the highest international standards.

Wide Application in Special Fields: Its oil - free scroll air compressors and oil - free screw air compressors are widely used in medical, pharmaceutical, food, bio - fermentation, electronics, and other industries with high - standard gas requirements. For example, in the medical industry, it can provide clean air for operating rooms and medical equipment; in the food industry, it can ensure food safety by providing clean compressed air for vacuum packaging, etc.

Intelligent Control: Each unit is equipped with a micro - computer control system, which has self - diagnosis and protection functions. It can prompt users to replace components and carry out necessary maintenance in a timely manner. The unit computer system has reserved spare output and input terminals, which can realize interlocking control of multiple units and remote control, facilitating operation and management.

Lead time and delivery?

Lead - time: Generally, for regular products, the lead - time may be relatively short. With reference to the industry, it is possible to deliver within 7 days. If it is a customized product, it may take longer. For example, some compressor manufacturers need 30 days for sample production and 60 days for mass production. Luoyou Compressor may have a similar situation, and the specific lead - time may also be affected by factors such as order quantity, production line load, and component supply.

Delivery Method: Usually, compressor manufacturers will adopt international logistics methods. If the customer is overseas, sea freight is a common choice, which is suitable for large - scale products and can reduce costs. If the customer is in the domestic market, it may be delivered by road or rail according to the distance, which can ensure timeliness and transportation safety. According to the previous order cases of Luoyou Compressor, the products are packed in wooden cases and shipped in containers, which is in line with the general practice of sea freight. In addition, if the customer has special requirements, air freight may also be considered, but this is usually more expensive and suitable for urgent or small - batch orders.

Warranty of main components

Common Warranty Period: For compressors, the warranty period for main components is usually 1 year. Considering that Luoyou Compressor's products focus on high - quality and reliable performance, the main components may also have a warranty period of about 2 years.

Factors Affecting the Warranty Period: The actual warranty period of Luoyou Compressor's main components may be affected by factors such as product models, usage scenarios, and user maintenance conditions. For example, if it is a model used in harsh industrial environments, the warranty period may be relatively short due to the high - load operation environment; while for models in general commercial scenarios, if the user maintains them according to the regulations, the warranty period may be closer to the upper limit.

Warranty Scope: Usually, the warranty scope covers failures or damages caused by manufacturing defects and material problems of the main components. However, problems caused by non - standard operation by users, such as using non - specified lubricants, voltage fluctuations exceeding the specified range, and unauthorized modifications to the equipment, are likely not within the warranty scope.

Keep in touch with us

Related Blogs

-

On the sunny day of November 21, 2024, four distinguished customers from Latin America visited our company with great anticipation to inspect our air compressor products. Upon entering, they were captivated by the neatly arranged and elegantly designed air compressors on display, and their eyes reflCompany News

On the sunny day of November 21, 2024, four distinguished customers from Latin America visited our company with great anticipation to inspect our air compressor products. Upon entering, they were captivated by the neatly arranged and elegantly designed air compressors on display, and their eyes reflCompany News -

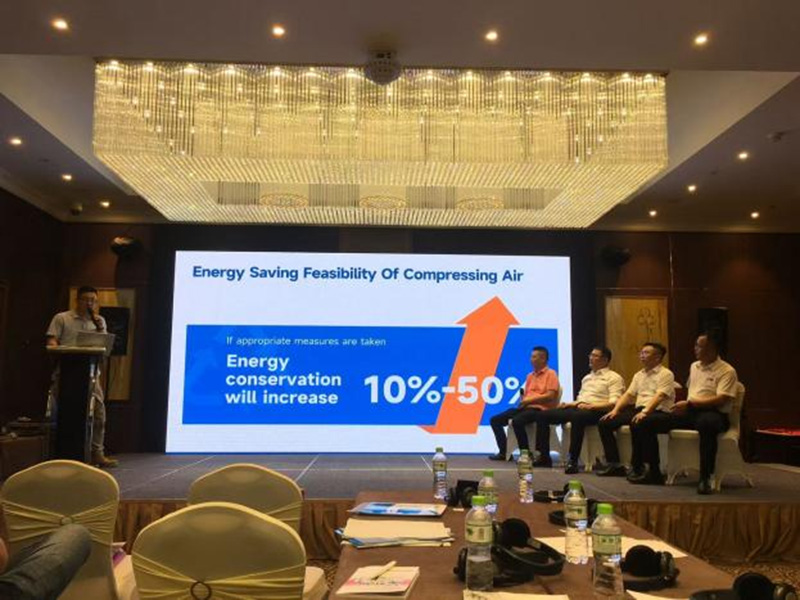

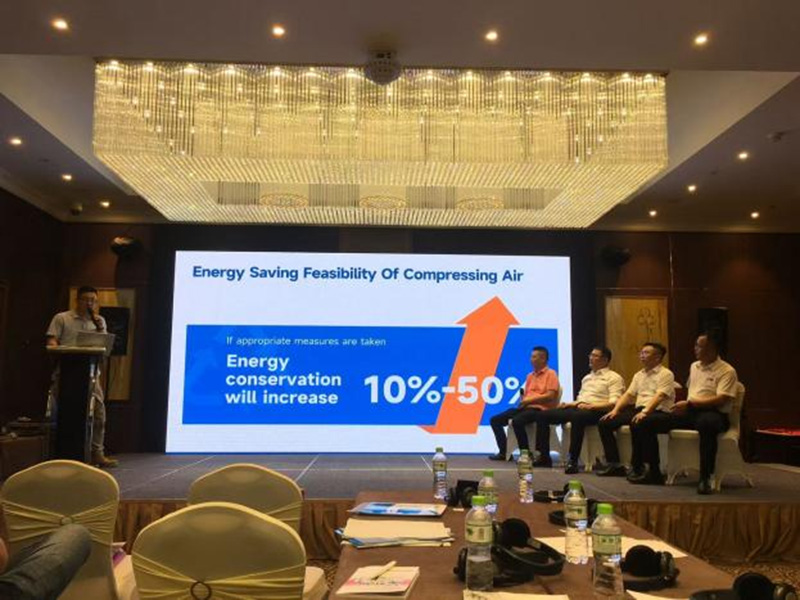

March 12, 2024, was recognized by our company as a pivotal moment for expanding into the international market. This significant day embodied our long-standing anticipation and enthusiasm in South-east Asia. After extensive preparations, our team, brimming with confidence, traveled across mountains aCompany News

March 12, 2024, was recognized by our company as a pivotal moment for expanding into the international market. This significant day embodied our long-standing anticipation and enthusiasm in South-east Asia. After extensive preparations, our team, brimming with confidence, traveled across mountains aCompany News -

As the first rays of dawn emerged, we successfully signed a cooperation agreement with our first client, laying a solid foundation for the project's implementation. During the afternoon business talks, the collision of ideas continuously sparked new cooperation inspirations. What moved us deeply wasCompany News

As the first rays of dawn emerged, we successfully signed a cooperation agreement with our first client, laying a solid foundation for the project's implementation. During the afternoon business talks, the collision of ideas continuously sparked new cooperation inspirations. What moved us deeply wasCompany News