- Home

- Products

- Hot

- About Us

- Services

- Industry

- Contact

Views: 0 Author: Site Editor Publish Time: 2025-12-15 Origin: Site

Selecting the right vacuum pump size is crucial for ensuring efficient operation across various industrial applications. An appropriately sized pump helps maintain optimal performance, reduces energy consumption, and prevents unnecessary wear and tear. Choosing the wrong pump size, however, can lead to significant consequences, such as energy waste, where the pump works harder than necessary, or insufficient vacuum, which can affect the quality and efficiency of the process. Additionally, an incorrectly sized pump may cause system stress, leading to premature failures and increased maintenance costs. Calculating the ideal vacuum pump size involves assessing key factors like flow rate, vacuum level, system losses, and application requirements. By carefully considering these aspects, you can ensure the pump is perfectly matched to your needs, optimizing both performance and cost-efficiency.

When selecting the right vacuum pump size for your operations, several key factors must be carefully evaluated to ensure optimal performance and efficiency:

The flow rate refers to the volume of air or gas that needs to be evacuated per unit of time, typically measured in cubic feet per minute (CFM) or liters per second (L/s). It’s essential to select a pump that can handle the required flow rate to maintain the efficiency of your process. If the flow rate is too high for the pump, it may struggle to meet demand, while an undersized pump will lead to poor performance and insufficient vacuum.

The vacuum level defines the degree of vacuum required for your application, usually measured in absolute pressure, torr, or mbar. Different processes demand specific vacuum levels, ranging from low vacuum to high vacuum. Choosing the correct vacuum pressure is critical for ensuring your process operates within the required conditions, whether it’s for precise semiconductor manufacturing, pharmaceutical production, or other applications.

The size and configuration of your system—including piping length, number of chambers, and any additional components—affect the vacuum pump's size requirements. A larger or more complex system will have more resistance and higher system losses, which will require a pump with a higher capacity. Properly sizing the pump to your system’s layout ensures it can handle the load efficiently without unnecessary strain.

Different applications (such as pharmaceuticals, semiconductor manufacturing, or food packaging) have specific requirements for both vacuum levels and flow rates. For example, pharmaceutical manufacturing may require an extremely high vacuum level for sterile conditions, while food packaging may need a pump that focuses more on flow rate for continuous operation. Understanding the specific needs of your application ensures that the pump you choose will be the most effective for the job.

Selecting the right vacuum pump size involves a detailed process that ensures optimal performance and efficiency. Here’s a step-by-step guide to help you calculate the ideal pump size for your application:

The first step is to determine the required flow rate, which is the volume of air or gas that needs to be evacuated per unit of time. This is typically measured in cubic feet per minute (CFM) or liters per second (L/s). The flow rate depends on factors such as:

The volume of the chamber or system that needs to be evacuated.

The frequency of operation, particularly for systems with continuous or high-volume use.

Calculate the flow rate based on the specific needs of your process to ensure the pump can handle the required workload without overburdening it.

Next, identify the vacuum level (or pressure) needed for your application. This is the degree of vacuum (measured in torr, mbar, or absolute pressure) required for the process. Different applications, such as semiconductor manufacturing, pharmaceuticals, or food packaging, require varying vacuum levels. Ensure that the chosen pump is capable of achieving the required vacuum level efficiently. If your process requires a very low vacuum, you’ll need a high-performance pump designed for that level of pressure.

Consider system losses, which include any reductions in vacuum efficiency caused by components such as piping, filters, and valves. These elements create resistance and pressure drops that impact the overall vacuum performance. For example, long or narrow pipes, clogged filters, and improperly sealed valves can significantly affect the pump’s efficiency. Factor in these losses when calculating the pump size, and ensure the pump is capable of overcoming them to maintain optimal performance.

Finally, assess the operational conditions, such as temperature and humidity, which can affect the pump’s performance. High temperatures or humidity levels can cause the pump to work harder, potentially reducing efficiency and lifespan. Take into account the environmental factors at your site and ensure the vacuum pump selected can perform effectively under those conditions. For example, extreme temperatures may require pumps with special cooling or sealing mechanisms.

Choosing the right vacuum pump model ensures efficient operation and meets application needs. Here's how to select the ideal pump:

Ensure the pump meets your application’s flow rate and vacuum level:

Flow Rate: The pump should handle the required volume of air or gas per unit of time.

Vacuum Level: Select a pump that can achieve the required vacuum level, whether for rough, medium, or high vacuum.

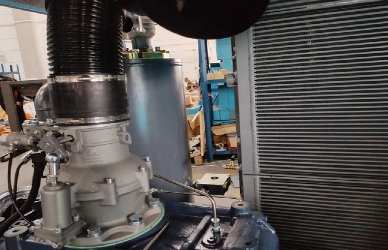

Rotary Vane Pumps: Suitable for general industrial applications with moderate flow rates and rough to medium vacuum levels.

Diaphragm Pumps: Ideal for contamination-sensitive applications, offering oil-free operation for low to medium vacuum levels.

Dry Pumps: Used in sensitive applications like semiconductors, offering oil-free operation at higher efficiency but at a higher cost.

Pump Size: Larger pumps handle more flow but may consume more energy. Smaller pumps are more efficient but may not meet high-demand needs.

Efficiency: High-efficiency pumps reduce energy costs but typically have a higher initial price.

Cost: Consider the total cost of ownership, factoring in energy use, maintenance, and lifespan, not just the upfront cost.

When selecting a vacuum pump, it’s important to avoid common mistakes that can lead to inefficiency, increased costs, and system issues. Here are key mistakes to watch out for:

Choosing a pump that’s either too large or too small can result in inefficiency:

Overestimating the size: A larger pump may consume more energy than necessary and increase operational costs.

Underestimating the size: A pump that is too small may struggle to meet performance requirements, leading to inadequate vacuum levels and system inefficiency.

Ensuring the right size is crucial for achieving the required performance while avoiding waste.

Failure to account for system losses—such as those from piping, filters, and valves—can result in an underperforming pump. These losses reduce the vacuum pump's efficiency, requiring it to work harder to maintain performance. Always factor in these losses during the sizing process to ensure the pump can compensate for system resistance.

Focusing only on the initial cost of a pump can be a costly mistake. While a cheaper pump may seem like a better option upfront, it may have higher energy consumption and maintenance costs over time. Opt for pumps with better long-term efficiency, as they can offer substantial savings in energy bills and reduce maintenance expenses, leading to better ROI.

A1: A properly sized vacuum pump should meet your application’s flow rate and vacuum level requirements without excessive energy consumption. If your pump is running inefficiently or unable to maintain the required vacuum, it may be undersized.

A2: While some vacuum pumps can be versatile, it’s essential to match the pump to the specific requirements of each application (e.g., flow rate, vacuum level). Using the wrong pump for a different application may lead to inefficiency or inadequate performance.

A3: System losses occur due to factors like piping resistance, filter clogging, or valve restrictions. These losses reduce the effective vacuum level and increase the size of the pump needed to compensate for the lost performance.

A4: The choice between an oil-lubricated and an oil-free pump depends on factors like contamination risk, maintenance requirements, and the cleanliness needed for your application. Oil-free pumps are preferred in contamination-sensitive environments, while oil-lubricated pumps tend to be more durable in industrial applications with less stringent cleanliness requirements.

Calculating the correct vacuum pump size is crucial for ensuring operational efficiency and cost-effectiveness in any application. An appropriately sized pump helps maintain the required vacuum levels without wasting energy or overworking the system. It's essential to use proper sizing methods and, when necessary, consult with experts to ensure the best performance for your specific needs. By carefully balancing energy efficiency, performance, and cost, you can select a vacuum pump that delivers reliable, long-term results while keeping operating expenses in check. Taking the time to properly size your vacuum pump will not only optimize efficiency but also contribute to a more sustainable and cost-effective operation.