- Home

- Products

- Hot

- About Us

- Services

- Industry

- Contact

Views: 0 Author: Site Editor Publish Time: 2025-07-23 Origin: Site

Laser cutting has revolutionized modern manufacturing, providing unparalleled precision, efficiency, and versatility for industries ranging from automotive and aerospace to electronics and metal fabrication. While the laser cutting machine itself is critical for accuracy and speed, auxiliary systems like air compressors play an equally vital role in ensuring consistent performance. Among these, screw air compressors have emerged as the preferred choice for laser cutting operations due to their energy efficiency, low noise, and reliability.

This article explores the advantages of energy-saving, low-noise screw air compressors in laser cutting applications, highlighting how they improve operational efficiency, enhance product quality, and contribute to a safer and more comfortable working environment.

Laser cutting systems rely on compressed air for several critical functions:

Cooling: Compressed air helps cool both the laser nozzle and the workpiece, preventing overheating, warping, or thermal damage.

Material Removal: It blows away molten metal or debris, ensuring clean, precise cuts without sticking or residue.

Oxidation Control: In certain metal cutting processes, compressed air can act as an oxidizing medium, producing cleaner edges and preventing discoloration.

Given these functions, the performance and reliability of the air supply directly affect the overall quality of laser-cut products. Fluctuating air pressure or contaminated air can lead to uneven cuts, surface defects, and increased waste. A reliable screw air compressor ensures a steady supply of clean, high-pressure air, enabling the laser to maintain precision even during extended production runs.

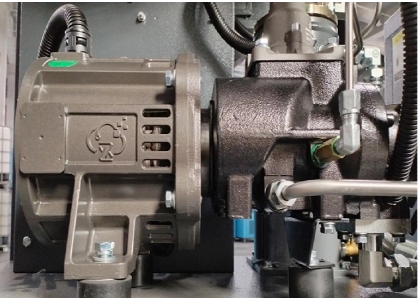

Screw air compressors have become the preferred choice for laser cutting applications due to a combination of performance, efficiency, and reliability. Their design and operational characteristics directly address the challenges posed by high-precision cutting environments.

One of the most important requirements for laser cutting is a steady and uninterrupted air supply. Unlike piston compressors, which operate in cycles and create pulsating airflow, screw compressors deliver continuous air flow. This constant supply ensures that the laser nozzle receives consistent pressure, which is crucial for maintaining precise cuts. Fluctuations in air pressure can lead to uneven material removal, rough edges, or variations in cut quality. With a screw compressor, manufacturers can maintain a stable production process, ensuring uniform results across every workpiece, even during long production runs.

The screw compression mechanism uses two interlocking rotors to compress air smoothly and efficiently, reducing energy loss that occurs in traditional piston systems. Many modern screw compressors also incorporate Variable Speed Drives (VSD), which dynamically adjust motor speed based on real-time air demand. This means the compressor operates only as hard as needed, conserving electricity during periods of lower usage. The result is not only lower operating costs but also reduced environmental impact. Energy-efficient operation aligns with modern manufacturing sustainability goals while providing a reliable air supply for critical laser cutting processes.

Industrial noise is a major concern in factories, especially where operators are required to focus on detailed tasks like laser cutting. Low-noise screw compressors feature optimized rotor profiles, sound-insulating enclosures, and vibration-damping technology to significantly reduce operational noise. A quieter environment improves worker comfort, minimizes fatigue, and enhances overall productivity. Additionally, reducing noise levels helps companies comply with occupational health and safety regulations, contributing to a safer workplace.

Space efficiency is another advantage of screw compressors. Their compact footprint allows them to be installed close to laser cutting machines, minimizing the length of air piping required. Shorter pipelines reduce pressure drops and energy loss, ensuring the laser receives consistent air pressure. The smaller size also allows manufacturers to optimize factory layouts, freeing up valuable floor space for other equipment or production processes.

Energy efficiency is a major consideration for manufacturers, and screw air compressors offer multiple benefits:

Reduced Power Consumption: Screw compressors operate with minimal friction, converting more input energy into usable compressed air.

Variable Speed Operation: VSD technology ensures that the compressor operates only at the speed needed, avoiding unnecessary energy use.

Lower Heat Generation: Efficient compression produces less heat, reducing cooling requirements and extending equipment lifespan.

By investing in an energy-saving screw compressor, manufacturers can reduce utility costs, meet sustainability goals, and improve the overall efficiency of their laser cutting operations.

Screw compressors are designed for long-term reliability with lower maintenance requirements than traditional piston compressors:

Fewer Moving Parts: Reduced wear points mean less frequent breakdowns and extended operational life.

Oil-Lubricated Rotors: Lubrication reduces friction and mechanical stress, protecting internal components.

Accessible Design: Modern compressors allow easy access to filters, oil tanks, and other consumables, simplifying maintenance.

Routine maintenance, including oil changes and filter replacements, keeps the compressor running efficiently and ensures consistent air quality, which is critical for laser cutting precision.

A stable and clean air supply from a screw compressor improves the quality of laser-cut products:

Smooth Edges: Consistent airflow removes molten material efficiently, preventing rough edges or burrs.

Precise Cuts: Steady air pressure maintains laser focus, producing accurate and repeatable cuts.

Reduced Defects: Clean, dry air minimizes oxidation and contamination, ensuring optimal surface finish and reducing material waste.

These factors are especially important in industries where precision is non-negotiable, such as aerospace components, electronics enclosures, or automotive body parts.

Screw air compressors for laser cutting are versatile and widely used:

Automotive: Cutting body panels, decorative trims, and chassis components.

Electronics: Fabricating precise metal enclosures and casings.

Aerospace: Producing high-precision structural components and brackets.

Metal Fabrication: General sheet metal cutting for industrial and commercial purposes.

Signage and Advertising: Crafting intricate letters and logos from metal or acrylic sheets.

By ensuring a reliable air supply, screw compressors enable manufacturers to meet tight tolerances and high-quality standards across various applications.

Low-noise screw compressors contribute to a safer and more comfortable work environment:

Noise Reduction: Reduced decibel levels minimize hearing fatigue and improve concentration.

Vibration Control: Damping technology prevents excessive vibration, protecting both the machine and operators.

Regulatory Compliance: Quieter operation helps meet workplace noise regulations, enhancing safety and employee well-being.

A comfortable and safe workplace leads to higher productivity, lower absenteeism, and improved employee satisfaction.

When selecting a screw compressor for laser cutting, manufacturers should consider:

Required Air Flow and Pressure: Ensure the compressor meets the specific air demand of the laser system.

Duty Cycle: Continuous operation requires a compressor rated for high-duty cycles.

Energy-Saving Features: Look for VSD and other energy-efficient technologies to reduce operating costs.

Noise Levels: Low-noise models improve the working environment and comply with safety standards.

Maintenance Accessibility: Easy access to components simplifies routine checks and prolongs equipment life.

Choosing the right compressor ensures consistent air quality, maximizes efficiency, and supports long-term operational goals.

Energy-saving and low-noise screw air compressors are essential components for modern laser cutting operations. By providing a continuous, stable air supply, these compressors improve cutting precision, product quality, and workplace safety. Their efficiency reduces energy consumption, while low noise levels create a more comfortable working environment.

Investing in a high-quality screw air compressor ensures reliable, cost-effective, and sustainable support for laser cutting operations across industries such as automotive, aerospace, electronics, and metal fabrication.

For more information on advanced screw air compressors tailored for laser cutting and other industrial applications, visit Luoyou Compressor (Shanghai) Co., Ltd.. Their expertise in energy-efficient and low-noise solutions makes them a trusted partner for manufacturers seeking reliability, precision, and workplace comfort.